Garment/Apparel Manufacturing – Kellwood International, U.S.A

Problem: At present there is no online data capturing and tracking available.

The precious operator time is lost in the process of cutting and inserting the barcode

labels for each operation from the bundles to the operator's worksheet. The section

supervisor has no real-time data on the WIP status at each process level. There

is no monitoring of key performance indicators in real-time that can proactively

resolve order fulfillment bottlenecks, compress time-to-market, and match supply

and demand.

There is a difficulty in real time decision-making that affects overall efficiency

and productivity.

ICEGEN RFID solution: RFID tags have been used in place of barcode labels.

The RFID tags are embedded with unique IDs already generated. These RFID tags are

then used to tie the bundles and the bundles are sent to the sewing section. At

each process station, the data on the RFID tag tied on the bundle is captured.

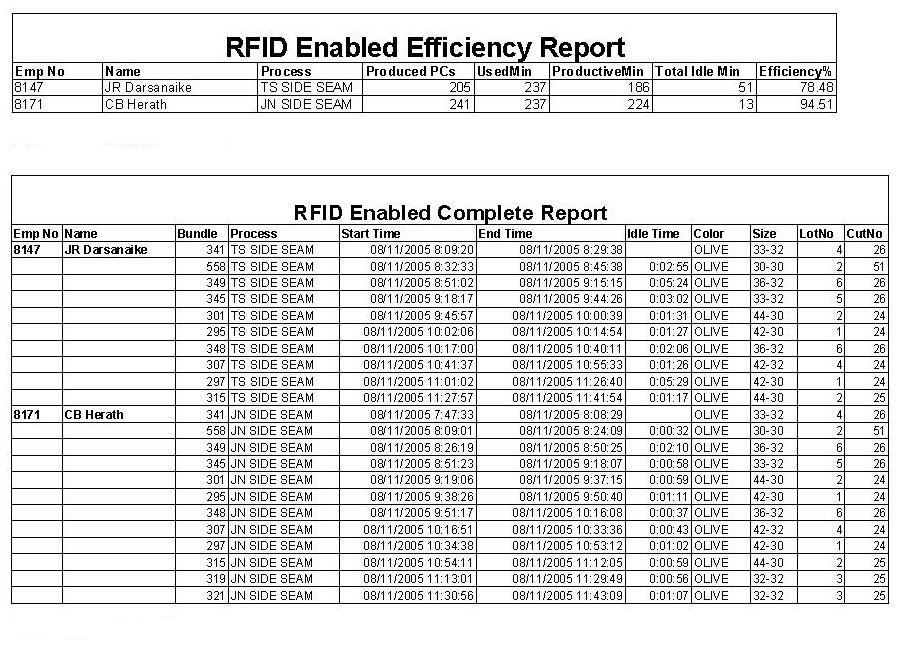

Thus the automatic capturing of the process start and end events and with the station

ID attached to the RFID Tag data, enables real-time status of the WIP.

ROI: Below are some of the ROIs with ICEGEN RFID solution

- Data is captured online and at real-time.

- A step-by-step electronic sign-off confirmation at every process.

- Real-time progress analysis and planning.

- Line balancing is done to get maximum efficiency and productivity.

- Control of malpractice in-case of overtime.

- Saves substantial amount of time by eliminating barcode printing, cutting and scanning.

- Facilitates derival of operator and operation efficiency against SAH(stipulated prefixed time) and productive minutes in real-time.

- Improves operational efficiency and supervisory control

- The system would also allow the supervisor to dynamically change the quantity of any bundle at any given point of the process.

- Tracking of work order completion status SKU wise against deadlines, in-case of backlog the supervisor can take effective steps on time.

- Incase a specific operator is doing multiple operations, they would be given process changeover tags which they can use to intimate the system about operation change.

- Total visibility across WIP

- Enables better workforce management, increases efficiency and productivity.