Home / Case Studies / Vehicle Exhaust Pipe Manufacturing – Arvin Manufacturing, Columbus Indiana

Vehicle Exhaust Pipe Manufacturing – Arvin Manufacturing, Columbus Indiana

Problem: Copper donuts break off and remain in exhaust pipe

posing significant financial risk.

ROI: RFID system installed ensures no exhaust pipe leaves the factory that is not completely clear of debris and will not pose an expensive burden once installed onto a car or truck at the next factory.

The photo shows a machine that automatically bends a pipe to a predetermined shape. A laborer will slide a straight pipe completely down the length of the mandrel. Arms and clamps at the front of the machine will grab the pipe and bend it in different directions, applying force left or right on the pipe at the end of the mandrel, to form the end result exhaust pipe. With each bend the mandrel will push the pipe further off to prepare for the next bend, and then eventually is pushed off into the laborer's waiting hands. At the end of the mandrel are soft copper donuts, which allow the pipe to bend but not break. From time to time, these donuts break off without the laborer realizing it. If a clogged exhaust pipe is sent to a car manufacturer and installed on a car, the costs of damage at that point are immense. Or if a laborer does not immediately recognize a donut is missing before the exhaust pipes are shipped. He has to examine 10,000 pipes produced that day!

Our Model 1771 RFID Tag is installed at the end of the donuts and above the machine you can see our Model 5120 Antenna, which is cabled back to our Model 7000E Reader, which is in turn interfaced to the machines operating system. This system verifies that the Tag is still in place, thus so are the donuts, before the machine can be started to manufacture the next pipe.

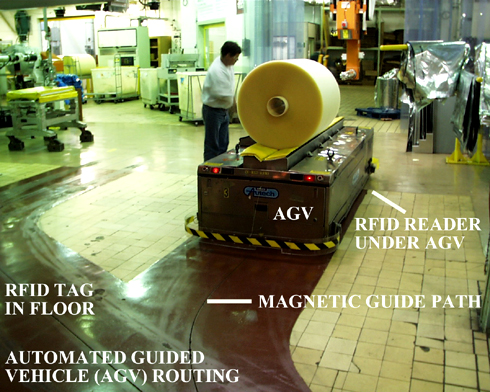

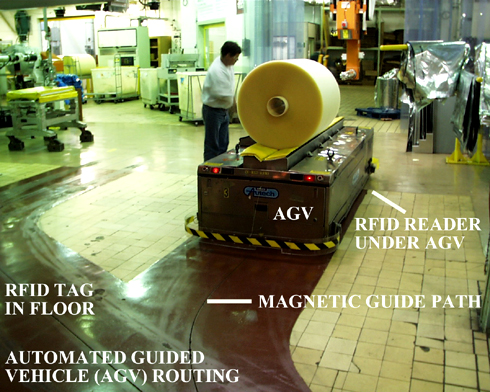

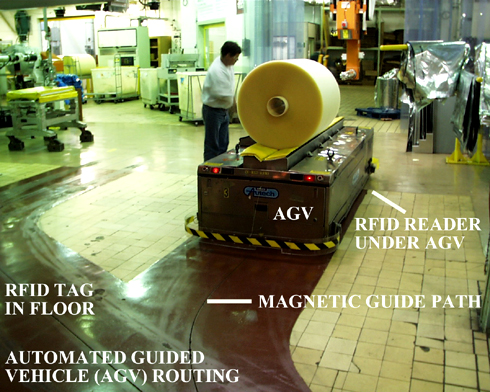

Automated Guided Vehicles (AGV)

All AGV (automated guided vehicles) applications are basically the same, the automatic routing of unmanned carts, usually with heavy or dangerous materials. The AGV's shown in our photos are at EI Dupont chemical factory where they manufacture a special plastic that goes between 2 pieces of glass that forms a car windshield. This special plastic will allow the windshield to shatter but not break, saving many thousands of lives in automobile accidents. This plastic is both heavy and must be put through volatile processes of dangerous chemicals.

All AGV (automated guided vehicles) applications are basically the same, the automatic routing of unmanned carts, usually with heavy or dangerous materials. The AGV's shown in our photos are at EI Dupont chemical factory where they manufacture a special plastic that goes between 2 pieces of glass that forms a car windshield. This special plastic will allow the windshield to shatter but not break, saving many thousands of lives in automobile accidents. This plastic is both heavy and must be put through volatile processes of dangerous chemicals.

There is a magnetic guide path in the floor that the AGV follows. Our Model 1787 Tags are buried in the ground. Naturally there is intelligent decision making on board the AGV linked to our Reader. A supervisor need only choose from a program residing on the AGV's computer, the type of material to be manufactured and the AGV then knows automatically which paths to take throughout the manufacturing facility and which door to proceed to for shipping when finished.

Why use AGV's? Humans make mistakes. A human could damage the materials by putting it through the wrong processes, especially if there are many long and detailed processes to go through. A human could wreck a forklift, hit someone with this very dangerous to the health material, or hit something and damage this very expensive material. Newspapers and printing facilities are normally the users of AGV's due to the large very heavy rolls of paper.

ROI: RFID system installed ensures no exhaust pipe leaves the factory that is not completely clear of debris and will not pose an expensive burden once installed onto a car or truck at the next factory.

The photo shows a machine that automatically bends a pipe to a predetermined shape. A laborer will slide a straight pipe completely down the length of the mandrel. Arms and clamps at the front of the machine will grab the pipe and bend it in different directions, applying force left or right on the pipe at the end of the mandrel, to form the end result exhaust pipe. With each bend the mandrel will push the pipe further off to prepare for the next bend, and then eventually is pushed off into the laborer's waiting hands. At the end of the mandrel are soft copper donuts, which allow the pipe to bend but not break. From time to time, these donuts break off without the laborer realizing it. If a clogged exhaust pipe is sent to a car manufacturer and installed on a car, the costs of damage at that point are immense. Or if a laborer does not immediately recognize a donut is missing before the exhaust pipes are shipped. He has to examine 10,000 pipes produced that day!

Our Model 1771 RFID Tag is installed at the end of the donuts and above the machine you can see our Model 5120 Antenna, which is cabled back to our Model 7000E Reader, which is in turn interfaced to the machines operating system. This system verifies that the Tag is still in place, thus so are the donuts, before the machine can be started to manufacture the next pipe.

Automated Guided Vehicles (AGV)

All AGV (automated guided vehicles) applications are basically the same, the automatic routing of unmanned carts, usually with heavy or dangerous materials. The AGV's shown in our photos are at EI Dupont chemical factory where they manufacture a special plastic that goes between 2 pieces of glass that forms a car windshield. This special plastic will allow the windshield to shatter but not break, saving many thousands of lives in automobile accidents. This plastic is both heavy and must be put through volatile processes of dangerous chemicals.

All AGV (automated guided vehicles) applications are basically the same, the automatic routing of unmanned carts, usually with heavy or dangerous materials. The AGV's shown in our photos are at EI Dupont chemical factory where they manufacture a special plastic that goes between 2 pieces of glass that forms a car windshield. This special plastic will allow the windshield to shatter but not break, saving many thousands of lives in automobile accidents. This plastic is both heavy and must be put through volatile processes of dangerous chemicals. There is a magnetic guide path in the floor that the AGV follows. Our Model 1787 Tags are buried in the ground. Naturally there is intelligent decision making on board the AGV linked to our Reader. A supervisor need only choose from a program residing on the AGV's computer, the type of material to be manufactured and the AGV then knows automatically which paths to take throughout the manufacturing facility and which door to proceed to for shipping when finished.

Why use AGV's? Humans make mistakes. A human could damage the materials by putting it through the wrong processes, especially if there are many long and detailed processes to go through. A human could wreck a forklift, hit someone with this very dangerous to the health material, or hit something and damage this very expensive material. Newspapers and printing facilities are normally the users of AGV's due to the large very heavy rolls of paper.